Polyvinyl chloride, commonly known as PVC, is a versatile plastic widely used in construction, healthcare, and consumer goods. While it brings convenience and durability to various industries, the question is PVC recyclable is not so simple to answer.

In this article, we’ll delve into the complexities surrounding PVC recycling, exploring its properties, challenges, and ongoing efforts to make this commonly used plastic more environmentally friendly. You can learn more about PVC, what it’s made from, why we use it, and common items made from PVC or Plastic number 3.

Understanding PVC: The Versatile Plastic

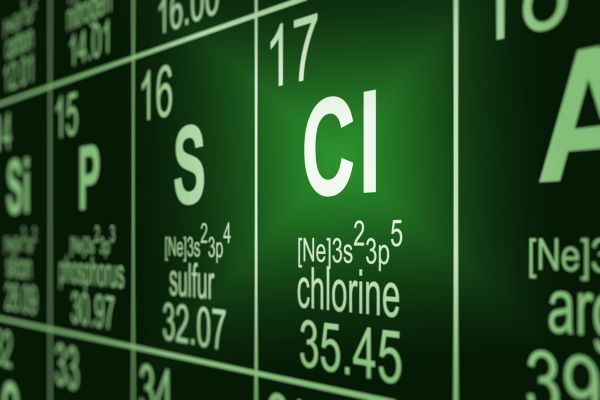

PVC is a synthetic polymer composed of carbon, hydrogen, and chlorine. Its versatility stems from its ability to be rigid or flexible, transparent or opaque, and resistant to chemicals, weathering, and corrosion. These characteristics make PVC a preferred material in the production of pipes, cables, clothing, medical equipment, and a myriad of consumer products.

However, the very properties that make PVC attractive also pose challenges when it comes to recycling. Unlike some other plastics, PVC contains chlorine, and its production involves the use of additives like plasticizers and stabilizers. These components contribute to its durability but complicate the recycling process.

The PVC Recycling Conundrum

The question “is PVC recyclable?” doesn’t have a straightforward answer. If the question is applied directly to post-consumer PVC, then the answer is more likely no; it cannot be recycled. This is primarily due to a lack of recycling facilities and the limitations around collecting this material. Most curbside recycling services cannot handle and, therefore, will not accept items made from PVC.

However, the recycling of PVC from industrial sources is on the increase. While technical challenges exist, ongoing efforts to improve PVC recycling methods and increase awareness about its environmental impact offer hope for a more sustainable future. The key lies in a multi-faceted approach that involves technological advancements, regulatory measures, and a collective commitment.

Is PVC Recyclable: A Look At The Challenges

One of the primary challenges in PVC recycling is its chlorine content, a characteristic that distinguishes it from many other commonly recycled plastics. The presence of chlorine adds complexity to the recycling process, as incineration or landfill disposal of PVC can result in the release of harmful chlorine gas, presenting both environmental and health risks.

Additionally, the additives used in PVC, including plasticizers and stabilizers, pose a significant hurdle to recycling efforts. While these additives enhance the material’s properties, they can contaminate the recycling stream, requiring meticulous separation of PVC from other plastics.

Moreover, the limited recycling infrastructure for PVC further complicates its sustainable disposal. Unlike more commonly recycled plastics like PET or HDPE, PVC lacks a widespread network of collection and recycling facilities. Consequently, a substantial amount of PVC often finds its way into landfills, exacerbating environmental concerns.

Even when PVC undergoes recycling, the process often results in downcycling rather than true recycling. The recycled material is typically repurposed for lower-value applications, and its overall quality and performance may be diminished. These downcycling concerns highlight the need for more sophisticated recycling methods and increased infrastructure to address the unique challenges posed by PVC recycling.

How is PVC recycled?

Polyvinyl chloride (PVC) recycling is a complex process due to the unique properties and additives present in this plastic. While PVC is not as widely recycled as some other plastics, efforts are underway to improve recycling technologies and increase the sustainability of PVC materials.

The recycling process typically involves the following steps:

- Collection: PVC waste is first collected from various sources, including post-consumer products, construction sites, and industrial processes. Collection methods vary, and the challenge lies in ensuring a consistent and clean supply of PVC for recycling.

- Sorting: Once collected, PVC waste is sorted from other materials in the recycling stream. Advanced sorting technologies, such as near-infrared sensors, are employed to separate PVC from other plastics. This step is crucial to prevent contamination in the recycling process.

- Cleaning: After sorting, the PVC material undergoes a cleaning process to remove contaminants, such as dirt, labels, and residual content from previous use. The cleanliness of the PVC is essential for maintaining the quality of the recycled material.

- Shredding: The cleaned PVC is then shredded into small pieces, increasing its surface area and facilitating subsequent processing. The size of the shredded PVC particles depends on the desired end product and the specific recycling technology used.

- Chemical Treatment or Mechanical Recycling: PVC can be recycled through either chemical treatment or mechanical recycling methods.

- Chemical Treatment (Depolymerization): In this method, the shredded PVC is subjected to chemical processes that break down the polymer into its original monomers. These monomers can then be used to produce new PVC without the need for extensive purification. Chemical treatment is a more advanced but less common recycling method for PVC.

- Mechanical Recycling: Mechanical recycling involves melting the shredded PVC to produce pellets or flakes that can be used in the manufacturing of new products. This method is more common.

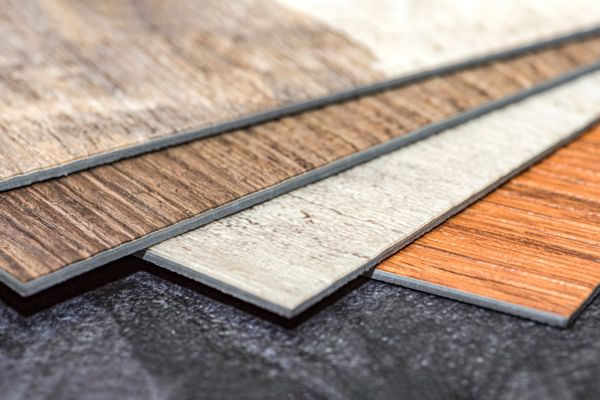

- Production of Recycled Products: The processed PVC is then used to manufacture new products. Recycled PVC can be incorporated into a variety of applications, including pipes, cable insulation, flooring, and packaging materials.

It’s important to note that while PVC recycling is possible, challenges remain, including the need to address the chlorine content and additives present in PVC. Innovations and ongoing research aim to improve the efficiency of PVC recycling and minimize its environmental impact.

The State of PVC Recycling Today

PVC recycling faces ongoing challenges, but some initiatives and advancements offer glimpses of hope for a more sustainable future:

- Voluntary Industry Initiatives: Some industries using PVC have implemented voluntary initiatives to address recycling challenges. For example, the Vinyl Institute in the United States has been actively working on improving PVC recycling and promoting sustainable practices within the industry. In 2023, they launched a first-of-its-kind industry-wide recycling grant program to help accelerate the recycling of post-consumer PVC in the US.

- Advancements in Technology: Research and development efforts have been focused on developing innovative technologies to improve PVC recycling. This includes more efficient sorting processes to separate PVC from other plastics and the development of recycling methods that can handle PVC’s unique properties. Recently, scientists at the University of Michigan discovered a way to recycle Polyvinyl chloride using an electrochemical method, which is improved by the presence of plasticizers.

- Circular Economy Principles: Embracing circular economy principles is crucial for the sustainable management of PVC. This involves designing products with recycling in mind, encouraging the use of recycled PVC in manufacturing, and establishing a closed-loop system that minimizes waste.

- Increasing Awareness: The growing awareness of environmental issues and the impact of plastics on ecosystems have prompted stakeholders to reevaluate their use of PVC. This increased scrutiny may drive industries to adopt more sustainable practices, including better PVC recycling.

Looking Ahead: Toward a Sustainable PVC Future

While PVC recycling faces challenges, ongoing efforts and emerging technologies signal a potential shift toward a more sustainable future:

- Research and Innovation: Continued research and innovation in PVC recycling technologies are essential. Investment in methods that can efficiently process PVC, separate it from other materials, and produce high-quality recycled PVC will be key to overcoming current limitations.

- Regulatory Measures: Governments and regulatory bodies can play a significant role in promoting PVC recycling by implementing policies that encourage responsible production and disposal. Extended producer responsibility (EPR) programs and incentives for using recycled materials may drive positive change.

- Industry Collaboration: Collaboration within the industry and across supply chains is crucial. Sharing best practices, collectively investing in research and development, and establishing recycled PVC standards can accelerate progress toward more sustainable practices.

- Consumer Awareness: Educating consumers about the recyclability of PVC, proper disposal methods, and the importance of supporting products with recycled content can influence purchasing decisions. Consumer demand for sustainable products often drives industry changes.

As we navigate the complex landscape of plastic recycling, PVC remains both a symbol of innovation and a challenge that requires collaborative solutions to balance its benefits with environmental responsibility. Unfortunately, for most consumers, the answer to “is PVC recyclable?” is No. Given how widespread the use of PVC is, lets hope this improves in the near term.