Polylactic Acid, commonly known as PLA, is a versatile bioplastic that has gained significant attention in recent years. Derived from organic renewable resources, PLA differs from most plastics and has emerged as a sustainable alternative to traditional petroleum-based plastics. It’s a biodegradable plastic generally made from cornstarch or sugar cane and is commonly used in food packaging.

In this comprehensive guide, we’ll delve into the origins, properties, uses, environmental impact, and recyclability of PLA.

What is PLA?

Polylactic Acid is a bio-based polymer derived from natural resources, primarily corn starch or sugarcane, but it can also be made from other plant materials such as cassava or maize.

The production process involves fermenting these plant sugars to produce lactic acid, which is then polymerized to form PLA. This bio-based approach distinguishes it from conventional plastics derived from fossil fuels, making it a more sustainable choice.

Why Do We Use Polylactic Acid?

The properties of PLA are very similar to several petroleum-based plastics in the plastic resin codes, such as polypropylene, polyethylene, and polystyrene (plastics number 5, 1, and 6 in the resin plastic recycling numbers).

One of the key features of PLA is its biodegradability, a property that its petroleum-based counterparts cannot compete with. Under certain conditions, it can break down into water, carbon dioxide, and organic compounds with the help of microorganisms, making it a more environmentally friendly option compared to traditional plastics that can persist in landfills for centuries.

The most attractive properties are its versatility and heat resistance. While it has a lower heat resistance compared to some petroleum-based plastics, recent advancements in PLA formulations have resulted in high-temperature variants suitable for certain applications like 3D printing.

PLA can be transparent or opaque, rigid or flexible, depending on the specific requirements of the intended application. This adaptability has led to it being used in many different industries.

In addition, PLAs reliance on renewable resources sets it apart. Using plant-based feedstocks reduces the carbon footprint, as plants absorb carbon dioxide during their growth, offsetting the emissions produced during production.

Common Items Made from PLA

What is PLA used for:

- Packaging: It’s commonly used in packaging materials such as containers, films, and wraps. Its transparent and moldable nature makes it suitable for showcasing food products while offering a more sustainable packaging solution.

- Single-Use Containers: PLA is a popular choice for single-use storage containers like takeaway cups, boxes, and utensils. This is because it can be sprouted as biodegradable or compostable, although, as we learned above, this is not always the case, depending on how it is disposed of.

- Textiles: PLA fibers have found applications in the textile industry, providing an eco-friendly alternative to traditional synthetic fibers. PLA-based fabrics are used in clothing, bedding, and various other textile products.

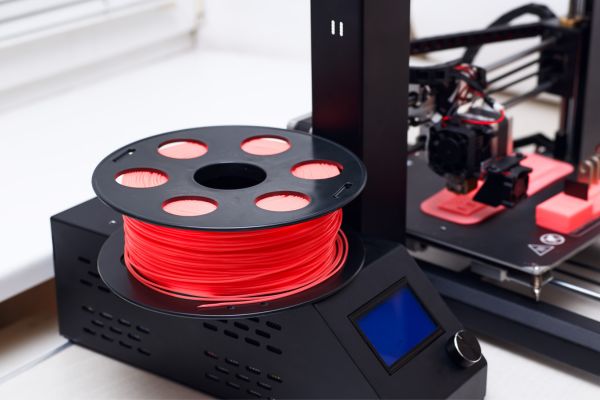

- 3D Printing: PLA has gained popularity in the field of 3D printing due to its ease of use, low toxicity, and biodegradability. 3D printed objects made from PLA are widely used in prototyping, hobbyist projects, and even in some industrial applications.

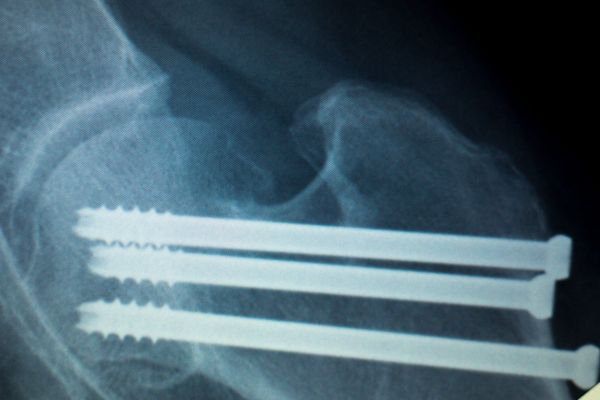

- Medical Devices: PLA’s biocompatibility and ability to degrade harmlessly make it suitable for certain medical applications, such as sutures and implants like rods and screws. Its use in medical devices aligns with the growing emphasis on sustainable practices in the healthcare industry.

Can PLA be Recycled?

Yes, PLA can be recycled; however, it is not in your curbside recycling bin. It is not recyclable because it is classed as biodegradable instead. It is not that PLA cannot be recycled. It’s that the recycling infrastructure for PLA hasn’t been scaled up yet; this is mainly because end markets for the recycled material haven’t been developed.

The recycling process typically involves collecting used PLA items, cleaning and shredding them, and then melting the shredded material to form pellets ready for manufacturing.

NOTE: If you are using PLA for 3D printing, a few sites explain how you can reuse your waste from printing with an at-home recycling machine. Or you can purchase recycled PLA filaments directly.

Is PLA Biodegradable or Compostable?

Polylactic acid (PLA) is often hailed for its eco-friendly properties, but it’s essential to clarify its biodegradability and compostability. PLA is indeed both biodegradable and compostable, but the nuances lie in the conditions required for these processes.

Biodegradability refers to the ability of a material to break down into natural substances through the action of microorganisms over time. PLA, under optimal conditions, can biodegrade into carbon dioxide, water, and organic compounds. However, the rate of degradation depends on factors like temperature, humidity, and the presence of specific enzymes.

Compostability, on the other hand, implies that a material can undergo a controlled biological decomposition in a composting environment, turning into nutrient-rich compost. PLA requires industrial composting facilities with specific conditions – elevated temperature, moisture, and microbial activity – for efficient breakdown. In a home composting setting, PLA may take longer to decompose, and in regular landfills, it might behave more like traditional plastics.

Understanding the dual nature of PLA’s biodegradability and compostability is crucial. While it holds promise as a sustainable alternative, proper waste management infrastructure and consumer awareness are pivotal for realizing the benefits.

What is Recycled PLA made into

Recycled PLA, or rPLA, can be molded into a variety of products, ranging from packaging materials and disposable cutlery to durable items such as bottles, trays, and even clothing fibers. The adaptability of rPLA highlights its potential to replace conventional plastics in numerous consumer and industrial sectors.

What happens when it’s not recycled?

When polylactic acid (PLA) is not recycled, its environmental impact diverges depending on its disposal route. When PLA ends up in the environment, such as in oceans or on land, it undergoes a slow degradation process.

Unlike traditional plastics, which persist for centuries, PLA breaks down into water, carbon dioxide, and organic compounds within a span of months to a few years. While this may seem positive, the breakdown process releases methane, a potent greenhouse gas, contributing to environmental concerns.

If PLA finds its way to a landfill, the lack of proper conditions for composting hinders its biodegradation. Landfills are designed to restrict the entry of air, essential for the breakdown of PLA. As a result, PLA in landfills behaves more like conventional plastics, occupying space for an extended period.

This emphasizes the importance of separating PLA from regular waste streams and diverting it to composting or recycling facilities when possible.

How to Reduce and Reuse

Reducing the consumption of polylactic acid (PLA) plastic involves adopting mindful practices to minimize waste and promote sustainability. You can have the biggest impact by reducing your consumption by buying less and using what you have.

Here are some tips to reduce the impacts of PLA:

- Avoid unnecessary single-use items by carrying reusable bags, utensils, and water bottles, reducing the reliance on disposable PLA products. This not only reduces the demand for new PLA production but also lessens the environmental impact associated with disposal.

- When you do use PLA items, dispose of them properly. If industrial composting facilities are available, dispose of PLA in compost bins. However, if these facilities are not available to you, prioritize recycling or explore alternative disposal methods to prevent PLA from contributing to landfill waste.

Conscious consumption plays a pivotal role. Educating yourself and others about PLA’s properties and its proper disposal methods is essential in ensuring it does not become an environmental issue.

Is PLA better than regular plastics?

Independent reports state that the process of making PLA produces 63% less greenhouse gasses and requires 65% less energy. But in order to compare PLA to other plastics, it would be necessary to conduct a life cycle assessment (LCA), which is crucial for understanding the overall environmental impact of materials. This assessment considers factors such as raw material production, manufacturing, transportation, product use, and end-of-life disposal.

Some of the problems with PLA plastic include:

- One of the issues of PLA is that it relies on agricultural crops, raising concerns about potential competition with food production. It takes a tremendous amount of material, such as corn, to produce PLA, and this could impact global markets, for example. Striking a balance between sustainable sourcing and avoiding negative impacts on food supply chains is a challenge that the PLA industry continues to address.

- The biodegradable nature of PLA can compromise the longevity of foods that are packaged in the material. The average lifespan of PLA film can be as little as 6 months, and this period of time starts from the manufacturing process and extends through packaging and delivery to retail stores and then sale to customers.

- Despite being recyclable and biodegradable, PLA faces challenges in existing recycling systems. Its compatibility with traditional recycling processes is limited, and its presence in recycling streams can contaminate other plastics. Developing a dedicated recycling infrastructure for PLA is an ongoing area of research and development.

- Polylactic acid (PLA) may inadvertently encourage the use of single-use items. The perception that PLA is biodegradable may lead to complacency in disposable consumption. Individuals may choose PLA-based products assuming they have less environmental impact, neglecting the importance of reducing overall single-use item usage.

The answer to whether PLA is better than fossil fuel derived plastics is a complex one and beyond the scope of this article. Either way, we still must focus on reducing our use of not only single-use items but all materials to minimize the impact on the planet.

Closing Thoughts: What is the role of PLA in the future?

In conclusion, Polylactic Acid (PLA) represents a promising step towards a more sustainable and eco-friendly future. Its biodegradability, renewable sourcing, and versatility make it an attractive alternative to traditional plastics. However, challenges such as recycling compatibility, land use concerns, and the need for advancements in technology persist.

As research and innovation in the field of bioplastics continue, PLA is poised to play a crucial role in reducing the environmental footprint associated with plastic production and consumption. However, it’s essential that the accessibility of waste management infrastructure for composting and recycling PLA not only catches up but keeps up.