It seems like a bit of a silly question. Of course, we all know what plastic is, right? We handle plastic items every day. It’s in almost everything we use, from plastic bottles to kitchen utensils, from cars and airplanes to building materials and roads.

Not only is it a big part of our everyday lives, but plastic has become a huge environmental problem. It’s all over the news headlines at the moment. Plastic pollution in the ocean, plastic waste in our rivers, clogging up our beaches, city streets, and parks. Plastic is everywhere!

The truth is, I had to admit that I didn’t know what it is. I had a vague idea, long lost memories from school, but I couldn’t explain it. I decided that it’s time I found out more.

Below is what I learned.

If you’d prefer to learn more about Curbside Recycling check these out.

- The Quick Reference Guide for Curbside Recycling

- Recycling Symbols and Meanings

- Plastic – How to make sense of Plastic by Numbers

- Glass – Glass recycling

- Paper & Cardboard – How to Recycle

- Metal – Metal Recycling Facts And The Recycling Process

What is plastic?

Plastic describes any material that can be shaped and molded when you apply heat or pressure. It’s not just one type of material but describes a vast range of materials with this common property.

Think of all the different types of plastics you handle every day. Here are just a few:

- plastic bags from the store

- your car door handle

- a pen to write with

- a lifesaving syringe for diabetics

- your kids’ favorite toy (this week at least)

- a container storing dinner in your fridge.

Plastic is everywhere. In the kitchen, in the bathroom, in the shed, in the office, in our shops and cafes, and our schools and hospitals.

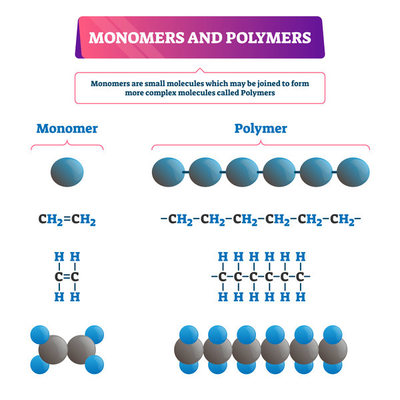

The reason plastic is so good at being made into so many different shapes is its molecular structure. All plastics are made up of compounds called monomers and polymers.

What are monomers?

Monomers are molecules made up of mostly organic compounds. The most important thing about monomers is its ability to create bonds with other monomers. They are the building blocks of polymers. When monomers are linked together, they can make giant molecules called polymers.

What are polymers?

Polymers are substances made up of long chains of thousands of monomers. Polymers can contain many thousands or even tens of thousands of monomers. The length and arrangement of the monomers within the polymer help to determine the properties of the plastic. These properties include things like strength, durability, clarity, flexibility, and elasticity. (1)

Polymers can be found in nature or can be made through chemical processes. Many of these natural polymers are not plastics. Plastics are actually just one type of polymer. The kind that has “plastic” qualities, meaning they can be molded easily.

Natural polymers occur everywhere around us and even in us. Our bodies are made up of many polymers, from our bones, skin, and hair. Even our DNA is made of polymers. Many foods we eat are made up of polymers. For example, the proteins in meat and milk, the starch in potatoes and pasta, and the cellulose in green vegetables.

Although nature provides us with many polymers, it doesn’t provide us with a lot of polymers that can be easily molded like plastics can. (Teegarden, D. (2004). page 5).

Types of Plastic. Thermoplastic vs. Thermoset

There are two main categories of plastics; they are thermoplastics and thermoset plastics.

What are thermoplastics?

Thermoplastics are plastics that soften when heated up and harden when cooled. They can be re-heated and will soften and melt again, allowing them to be remade into new products. A process that can be repeated multiple times. Some examples of thermoplastics are polypropylene, polyethylene, polystyrene, or polyvinyl chloride. These are used in many everyday items like:

This ability to be re-heated and reformed into new products means Thermoplastics can generally be recycled easily.

What are thermosets?

Thermoset plastics will not melt once they have been hardened for the first time and cannot be remolded. This is a useful property for some applications, such as machinery parts or items that need to withstand heat like light fittings.

The most commonly known thermoset example is Bakelite, which plays an important role in plastics’ history. Some other examples of thermosets are silicon, epoxy, polyurethane, and melamine. These plastics can be found in:

- electronic chips

- dental fillings

- the lenses of glasses

- the handles on appliances

- plastic crockery

- countertops

Unfortunately, the properties of thermosets mean that most of the products made using this type of plastic cannot be recycled.

Did you know: Some polymers can be formed into both thermoplastic and thermoset materials. An example of this is polyester.

Thermoplastic

Examples – Polypropylene, Polyethylene, Polystyrene, Nylon

Thermoset

Examples – Bakelite, Melamine, Silicone, Epoxy

How is plastic made?

Plastics are often made from petrochemicals like crude oil but can also be made from other materials. Some examples are natural gas or even corn, wheat, or rice. The first human-made plastics were actually made using cellulose from plants. In fact, cellulose acetate is still used to make some screwdriver handles and gift ribbon today.

Making plastic from crude oil first requires you to obtain the crude oil by drilling it and transporting it to a refinery. The crude oil is processed at the refinery to separate the different hydrocarbons. This process is called cracking. Cracking produces common products such as petrol/gasoline and diesel fuel.

During the cracking process, the monomers ethylene and propylene are produced. These monomers are then made into polymers through a process called polymerization. Once the polymers are created, other chemicals may be added to change how the plastics look and behave. This is how manufacturers create all sorts of products.

Some examples of additives that might be used are:

- Dyes to create different colors

- Plasticizers for flexibility

- Stabilizers to protect from breaking down in sunlight

- Flame retardant chemicals to reduce the risk of burning

These are just a few examples of some of the chemical changes made to plastics. Many different chemicals can be added to the plastic to create lots of additional features in the end product.

This addition of different chemicals creates a complex group of materials. These complex materials lead to a lot of confusion when it comes to disposing of plastic items. This is one of the things that can make recycling plastic so tricky. Knowing which plastic an item is made of and whether it can be recycled is not easy.

Manufacturing plastic products?

The plastic must now be shaped into a useful product. This is done at a factory where the plastic is molded into shape by melting, shaping, and solidifying it. Generally, the plastic is softened, and then it is either injected into a mold, shaped over a mold, extruded through a die, or laminated.

Each of these methods can be completed in different ways. Some examples are ram extrusion, compression molding, injection molding, blow molding, or casting, to name a few.

Finally, after the product has been shaped, it may undergo some finishing touches such as joining, machining, or coating. The result can be seen in the multitude of products found throughout your house.

It’s good to consider this lengthy and complicated process when considering the plastic items you already own. It is even more important to consider this when you are looking at buying something new made of plastic.

Wrap-up

The term “Plastic” is much more complicated than you might initially consider. The term doesn’t simply refer to one type of material but rather describes a group of materials with similar properties. Essentially, plastics can be shaped and molded when heat or pressure is applied to them.

Plastics are made of polymers, which in turn are made up of many, sometimes thousands, of monomers. These polymers give the plastic its properties.

There are two main categories of plastics, thermoplastic and thermosets. Thermoplastics can be melted repeatedly, while thermosets can no longer be melted once the initial product is created. These categories help determine if a particular plastic can be recycled or not.

It’s important to remember that the process of making plastic is a long and complicated one. This can make identification and recycling difficult. It’s worth keeping this in mind when you are at the shops buying new products.

Next

To keep learning about plastics and plastic recycling by numbers check out the following articles.

- Freinkel, Susan. (2011), Plastic, A Toxic Love Story, Melbourne Australia, The Text Publishing Company

- Teegarden, David M. (2004). Polymer Chemistry: Introduction to an Indispensable Science. NSTA Press.

- Freudenrich, Craig, How Plastics Work

- Evans, D. and Watkins, S., Polymers: from DNA to rubber ducks

- Explainthatstuff, (2019), Plastic

- Pleasant, R., (2016), Oil to Plastic: A Lesson On How Plastic Is Made

- American Chemistry Council, Life cycle of a plastic product

- Ferdinand Rodriguez, Britannica, Plastic

- Wikipedia Plastic

- Harrison, R.M. and Hester, R.E., (2018), Plastics and the Environment, Royal Society of Chemistry.

- Caitlyn, Scaggs (2014), Thermosets vs. Thermoplastics: As Explained by Party Trash

- Wilhelm, Richard. “Resin Identification Codes—New ASTM Standard Based on Society of the Plastics Industry Code Will Facilitate Recycling“. Standardization News (September/October 2008). ASTM International.